Become your trusted floor drain product partner and supplier in China.

Tel: +86-576-87422105, Email: [email protected]

"Nothing is best,only better". Better people are sincerely willing to cooperate with new and old customers. Let's hand in hand,and create the bright future together.

+86-576-87422105 Contact UsRecessed Linear Drain is increasingly used in modern bathrooms, showers, kitchens, and commercial spaces due to its sleek aesthetic and efficient water drainage capabilities. One critical aspect of its functionality is the design of the drain outlet, which directly affects its ability to prevent blockage from debris, hair, or other materials. Effective outlet design ensures continuous water flow, reduces maintenance needs, and maintains hygienic conditions. Understanding how outlet geometry, filtration, and positioning contribute to clog prevention is essential for both designers and users.

The physical shape and size of the Recessed Linear Drain outlet play a pivotal role in preventing blockages. Narrow or poorly positioned outlets can trap debris, while larger, optimally shaped channels allow water and small particles to pass through more freely. Linear drain outlets are typically elongated and designed with gentle slopes that flow into the drainage channel. This geometry helps direct water efficiently toward the outlet while reducing areas where debris can accumulate. Properly engineered outlet shapes reduce the likelihood of clogs and improve the overall drainage efficiency.

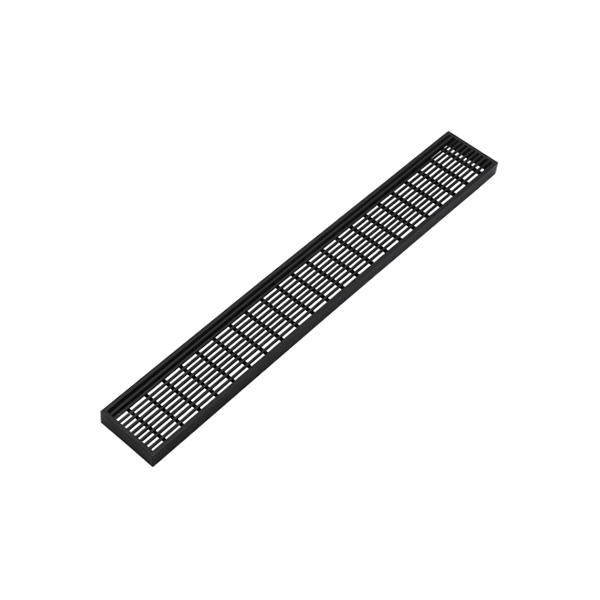

Grates or covers placed over the drain outlet serve as the one line of defense against clogging. High-quality Recessed Linear Drain products feature removable or finely meshed grates that allow water to flow while catching larger debris such as hair, food particles, or dirt. The spacing and material of the grate are critical; if the openings are too large, debris may pass through and cause clogs, while overly fine meshes can slow drainage or trap smaller particles. Well-designed grates strike a balance between efficient water flow and effective debris interception.

The placement of the outlet and the slope causing it are essential in maintaining a clog-free system. Recessed Linear Drains are typically installed along the perimeter or center of a floor surface, with a subtle gradient directing water toward the channel. A consistent slope ensures that debris does not settle in low spots and is instead carried along with the water flow toward the outlet. Incorrect slope or uneven installation can create stagnant areas, increasing the risk of blockages despite a well-designed outlet.

Even with a well-engineered outlet, periodic maintenance is necessary to prevent clogs. Removable grates facilitate easy cleaning, allowing users to clear trapped debris and maintain consistent water flow. Some designs include integrated filters or strainers that capture fine particles, reducing the frequency of deep cleaning. Accessibility and ease of maintenance are key features that complement the outlet design, ensuring that the drain continues to operate effectively over its lifetime.

The materials used in the Recessed Linear Drain outlet and grate can also influence clog prevention. Corrosion-resistant metals or high-quality polymers prevent degradation that could create rough surfaces or irregularities where debris may accumulate. Smooth, durable materials support efficient water flow and reduce the likelihood of blockage over time. Selecting appropriate materials enhances both the longevity and reliability of the drainage system.

The outlet design of a Recessed Linear Drain is fundamental in preventing clogs and maintaining efficient water flow. Through careful consideration of outlet geometry, grate design, slope, positioning, material selection, and maintenance accessibility, manufacturers can reduce the risk of blockages. Properly engineered outlets ensure continuous drainage, reduce maintenance requirements, and enhance the overall hygiene and functionality of the space. By prioritizing these design principles, Recessed Linear Drains provide reliable, long-lasting performance across a variety of applications.

Copyright © Yuhuan Better Machinery Co., Ltd. All rights reserved

English

English Español

Español عربى

عربى